Introduction to UV Printing Technology

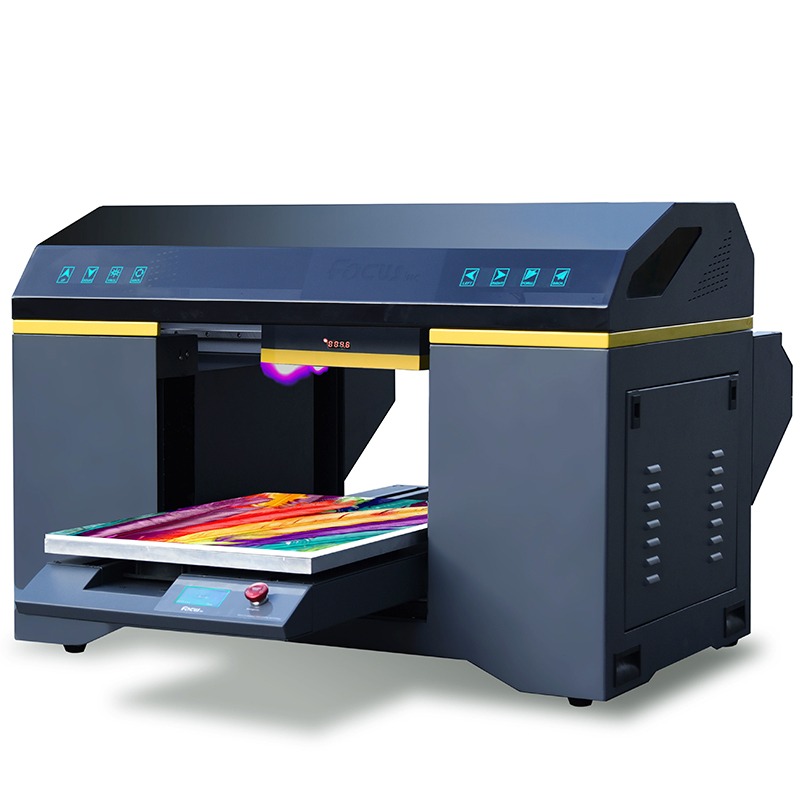

UV printing technology stands out in the digital printing landscape. A UV printer cures ink instantly using ultraviolet light. This quick-drying process ensures crisp, high-quality prints on diverse surfaces. From plastics to glass, the applications are endless. Unlike traditional methods, UV printing does not require solvents. This means less environmental impact and reduced waste. ‘UV printer’ often describes a flatbed device. This machine prints directly onto flat or slightly curved materials. For businesses and creatives, it opens a world of possibilities. UV printers support high precision and detail, critical for intricate designs. With this tech, small runs of personalized items become cost-effective. Speed, efficiency, and versatility are the hallmarks of UV printing.

The Versatility of UV Printers in Different Industries

UV printers have reshaped the printing scene across various sectors. Their immediate drying technology and adaptability have made them ideal for multiple industrial applications. Let’s explore how they stand out in different industries.

Personalized Products and Customization

The demand for personalized items is soaring. UV printers cater perfectly to this trend. They allow for high-detail customization on items like phone cases, mugs, and even guitar picks. Small businesses can thrive by offering one-of-a-kind products that cater to individual tastes. The UV printer’s ability to adhere to different materials makes it a top choice for customization.

Commercial Signage and Packaging

In the retail space, visibility is key. UV printers excel in producing vibrant, eye-catching signage and packaging. They can print on a vast array of materials, including plastic and carton, with durable and long-lasting results. This makes them a go-to for businesses looking to make a strong visual impact on their customers.

Industrial Applications and Prototyping

Beyond commercial use, UV printers are powerful tools in industrial design and prototyping. They help in creating detailed mock-ups and functional prototypes, speeding up the development process. Manufacturers appreciate the precision and quick turnarounds that UV printers offer, making them essential in the prototyping phase.

Comparing UV Printers with Traditional Printing Methods

When evaluating print technologies, it’s crucial to compare UV printers with traditional methods. Traditional printing often involves offset or screen printing techniques. These methods use inks that dry through evaporation, which can take time. They also might need additional drying processes. On the other hand, UV printers employ ultraviolet light to cure the ink. This brings numerous benefits.

UV printers stand out for their instant drying capabilities. This speeds up production and eliminates the wait time associated with ink evaporation. Also, UV printers don’t use solvents. Therefore, they are more environmentally friendly than some traditional practices that rely on solvent-based inks. Traditional methods may result in ink bleed on certain materials, but UV printing offers precision and reduced smudging on a variety of surfaces.

The cost efficiency of UV printers compared to traditional methods is another key factor. While traditional printing may require creating plates or screens for each job, UV printing does not. This makes UV printing more suitable for short runs and unique, one-off prints. The cost and time savings are significant, especially for small businesses and entrepreneurs.

Lastly, UV printers have a smaller footprint both in size and environmental impact. Traditional methods often involve large machinery and a high volume of waste. UV printers are more compact and produce less waste. With the push towards more sustainable practices, UV printing is becoming the preferred choice for many.

In summary, UV printers offer speed, environmental benefits, cost savings, and versatility. These advantages make them a competitive option over traditional printing methods.

Essential Features to Look for in a UV Printer

When shopping for a UV printer, certain features are crucial for top performance. Here are some you should consider:

High-Quality Print Heads

Choose printers with advanced print heads. They ensure sharp images and fine details.

Wide Material Compatibility

A good UV printer works on many materials. It should print on metal, glass, and plastics with ease.

Efficient UV Curing System

The curing system must be powerful. It ensures quick drying and durable prints.

User-Friendly Interface

Look for a simple interface. It should make setting up and operating the printer easy.

Robust Inks and Color Representation

Quality inks are important. They provide vibrant colors and long-lasting prints.

Safety Features

UV printers should have safety features. These protect users from UV exposure.

After-Sales Support and Warranty

Good customer support is essential. Ensure there’s a strong warranty and helpful tech support.

Scalability and Upgradability

Pick a printer that can grow with your business. It should allow upgrades and expansions.

Deciding on a UV printer involves checking these features. They affect print quality, usability, and safety. Make sure your choice ticks all these boxes. It should match your needs for creative and customized printing jobs.

Creative Projects You Can Achieve with UV Printing

The world of digital printing has expanded with the use of UV printers. Creators can now bring their visions to life in ways previously unimagined. Artists, marketers, and businesses alike can leverage the unique capabilities of UV printing. Let’s delve into the types of creative projects made possible.

Artistic Creations on Unconventional Materials

UV printers shine when it comes to art on atypical surfaces. They print on materials like acrylic, wood, and even leather. Imagine vibrant artwork on a wooden table or a detailed illustration on a guitar. With UV printing, artists push the boundaries. They transform everyday objects into stunning works of art. Canvases are no longer just linen or cotton; they can be any surface a UV printer can touch.

UV printing also supports textures and raised effects. Artists create tactile pieces that stand out both visually and physically. The result is often a more engaging and interactive experience for the viewer, making each piece even more memorable.

Tailored Marketing Materials and Corporate Branding

UV printing stands out in producing marketing materials. Businesses use UV printers for eye-catching promotional items. They create custom pens, USB drives, and even name badges. Each item carries the company’s signature style and brand colors.

Corporate branding extends beyond giveaways. UV printers create large-format displays and bespoke office decor. They ensure consistent branding across all materials. Businesses make a strong, cohesive statement about their identity and values. High-quality prints on office partitions or branded customer gifts showcase a company’s attention to detail and quality.

UV printing’s advantage lies in its customization potential. It allows for small-run prints without the high costs associated with traditional methods. Businesses personalize materials for specific events or clients, adding a touch of exclusivity and value to their marketing efforts.

In short, UV printers transform creative concepts into tangible realities. They cater to a wide range of projects. Whether it’s intricate art or professional branding, the possibilities are endless with UV printing technology.

Maintenance Tips for UV Printers to Ensure Longevity

To maintain the performance of a UV printer and ensure its longevity, follow these tips:

Regular Cleaning

- Keep the print heads clean to prevent clogs and ensure clear prints.

- Wipe down the exterior surfaces to keep the printer dust-free, focusing on ventilation areas.

- Clean the curing lamps. Dust reduces their effectiveness.

Inspections and Replacements

- Regularly check for any worn or damaged parts. Replace as needed.

- Inspect UV bulbs and replace them before they burn out to avoid downtime.

Software Updates

- Update the printer’s software regularly for improved functionality and new features.

Using the Right Supplies

- Use manufacturer-recommended inks and materials. They prevent damage and assure quality prints.

Controlled Environment

- Operate the UV printer in a climate-controlled space. Temperature and humidity affect its performance.

Professional Servicing

- Schedule annual check-ups with a certified technician. They will address potential issues early on.

Training for Staff

- Ensure that all operators are fully trained in proper use and maintenance protocols.

Adhering to these maintenance practices will help your UV printer to operate smoothly. It will also extend its service life, allowing you to maximize your creative output without interruption.

Case Studies: Innovative Uses of UV Printers in Business

The versatility of UV printers has allowed businesses to explore innovative printing possibilities. Here we present a few case studies that demonstrate the transformative impact of UV printing in various industries.

Custom Décor Company Creates Unique Interiors

A decor company used a UV printer to produce custom wallpapers and furniture finishes. They printed high-quality, detailed patterns directly onto large panels, giving designers more creative flexibility. With UV printers, they met clients’ specific design needs, providing one-of-a-kind interiors.

Local Brewery Revamps Branding with High-Quality Labels

A local brewery turned to UV printing for their bottle labels, ensuring each label was vivid and scratch-resistant. They were able to print in smaller batches, allowing for special edition releases. It was a cost-effective solution that enhanced their brand’s appeal.

Prototyping Firm Accelerates Time-to-Market

An industrial design firm integrated a UV printer for rapid prototyping. They produced precise, full-color models quickly, speeding up the revision process. This led to faster product development and a significant reduction in time-to-market for their clients.

Memorabilia Shop Offers Personalized Souvenirs

A souvenir shop took advantage of a UV printer to offer personalized mementos. They printed customers’ photos and text onto a variety of objects, from keychains to photo frames. The shop provided a unique service that stood out among competitors.

These case studies show that UV printers are not just for traditional print products. They empower businesses to customize, innovate, and adapt to market demands. The UV printer has become an essential tool for companies aiming to distinguish themselves through quality and creativity.

Conclusion: Unleashing Potential with UV Printing

UV printers are revolutionizing the printing world. They offer quick, high-quality runs on many materials. Art, marketing, and industry all see the effects. UV printers give unique chances for creative jobs. They beat old methods with speed, quality, and eco-friendliness.

These printers are perfect for custom works. They handle small orders well. This is great for small businesses targeting niche markets. With low costs and high detail, UV printing makes special designs possible.

Beside business, artists love these printers too. They print on new materials and make art that stands out. With UV printing, imagination is the only limit. Art can be more than just visuals. It can be tactile and interactive. This breathes new life into the art world.

For brands, UV printing helps make strong impressions. It offers customization that catches the eye. This enhances a brand’s message. It makes a company memorable to clients and partners.

Maintenance is key for UV printer success. Regular care keeps them running at their best. This includes cleaning, checking parts, and proper use. These actions help the printer last long, saving money and stress.

To wrap up, UV printing is not a trend. It’s a mainstay in the printing industry. It opens doors to unmatched creative freedom. It supports custom work that gets noticed. With a UV printer, the potential to create and impact is limitless.