Benefits of Having a 3D Printer Enclosure

Creating a dedicated space for your 3D printer has many benefits. A 3D printer enclosure, specifically tailored for your device, enhances the overall printing experience. Here we will discuss the key advantages.

Consistent Print Quality

An enclosure helps maintain a stable temperature around your 3D printer. This consistency improves print quality by preventing warping. Warping occurs when different parts of the print cool at varying rates. An enclosure ensures uniform cooling leading to better print results.

Reduced Noise

3D printers can be noisy when in operation. An enclosure acts as a sound barrier, muffling the noise produced. This reduction is beneficial if you have your printer in a shared space or residential area.

Improved Safety

The enclosure contains potentially harmful fumes emitted during printing. It also serves as a barrier, keeping pets and curious hands away from hot components. As a result, the printing process becomes safer for everyone around.

Enhanced Durability

With an enclosure, your 3D printer has protection from dust and external elements. This protection can extend its lifespan. Less dust means less maintenance and cleaner mechanical parts.

Temperature Control

Some materials, like ABS, need higher temperatures to print effectively. Enclosures help in retaining heat which is crucial for such materials. They enable a broader range of materials to be used with improved outcomes.

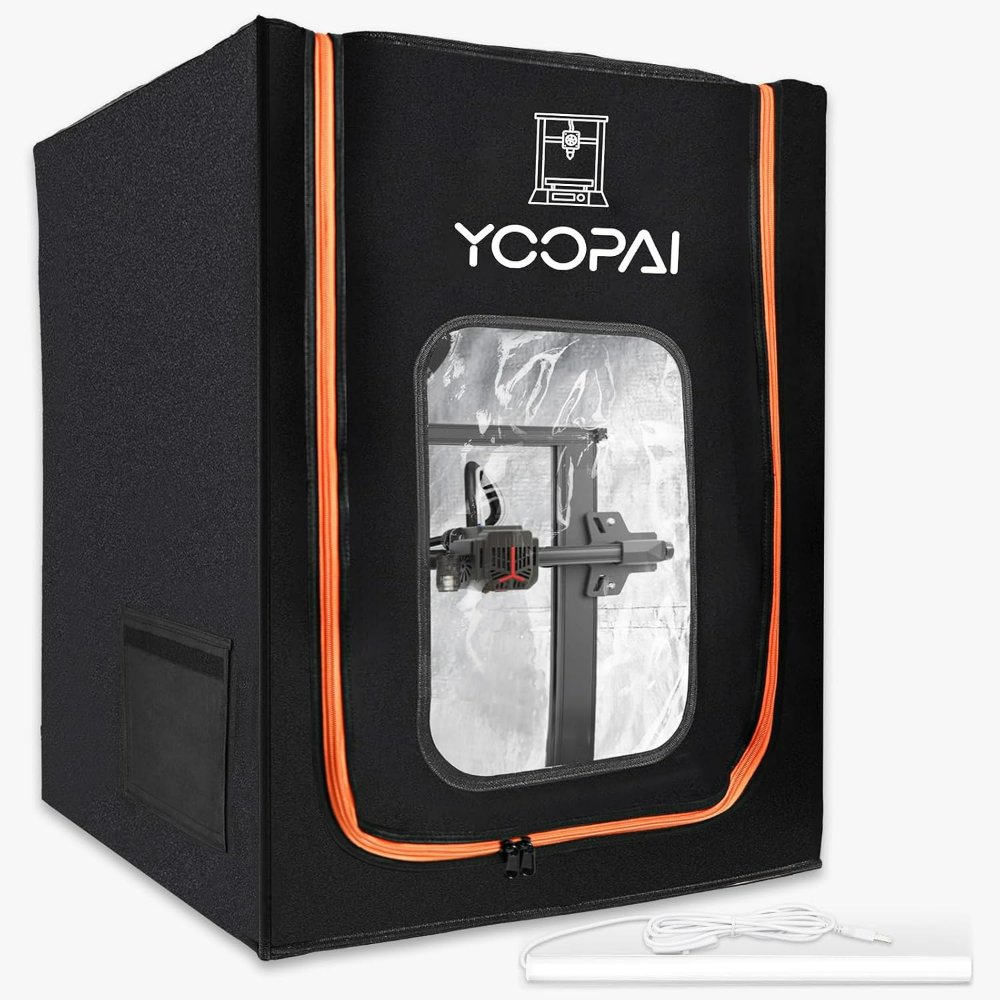

Aesthetic Appeal

Finally, a well-designed 3D printer enclosure can look professional and tidy. This aesthetic appeal might be important if your printer is in a visible area. It can also serve as an inspiration for your DIY projects.

An enclosure is an excellent investment for any 3D printing enthusiast. Not only does it improve the print process, but it also adds an extra layer of safety and functionality. As we explore further how to build your enclosure, keep these benefits in mind.

Key Considerations Before Building Your Enclosure

Before diving into the construction of your 3D printer enclosure, there are important factors to consider. Planning ahead will save you time and ensure that the enclosure meets your needs.

Material Choices for Your Enclosure

Selecting the right materials for your enclosure is crucial. The material should resist high temperatures and have stability. Common choices include acrylic, polycarbonate, and wood. Acrylic and polycarbonate provide visibility and are easy to work with, but wood can offer more rigidity and insulation. Think about durability, ease of modification, and overall cost when choosing.

Sizing and Space Requirements

Your enclosure must fit your 3D printer with additional space for movement and upgrades. Measure your printer and consider future modifications. Ensure there’s also enough room for ventilation systems and cable management. Leave clearance space for easy access and maintenance. Remember, the size of the enclosure influences the space you’ll need in your work area. Plan accordingly to avoid cramped conditions.

Step-by-Step Guide to Building a DIY 3D Printer Enclosure

Building a DIY 3D printer enclosure can be a satisfying project. It’s a step towards better quality prints and a safer environment. In this guide, we’ll walk you through the process from start to finish.

Tools and Materials Needed

Before beginning, gather your tools and materials. Essential items include measuring tape, a saw for cutting materials, screws, drill, screwdriver, and a sealant for insulation. Choose your materials wisely, as discussed earlier, considering durability and heat resistance. Acrylic, polycarbonate, or wood are top picks for most DIYers.

Designing Your Enclosure

Start with a clear design. Think about the size of your 3D printer and additional space needed. Sketch a blueprint that includes room for all features. Consider ventilation and access points. Keep the design simple for easy construction and maintenance.

Construction Process

The construction is a step-by-step execution of your design. Cut the selected materials to match your blueprint. Assemble the frame carefully, securing all edges and corners. Install any doors or access panels. Apply the sealant to ensure a good thermal seal. If you’re using acrylic or polycarbonate, remember to remove the protective film before assembling.

Ensure your 3D printer fits snugly inside and that there’s room for cables and necessary components. Attach the ventilation system if applicable, and check that all parts are secured. Once assembled, it’s time to enjoy the benefits of your new enclosure.

Ventilation and Temperature Control Systems

An effective 3D printer enclosure must include proper ventilation and temperature control systems. These features are vital for maintaining a consistent printing environment and ensuring user safety.

Importance of Proper Ventilation

Proper ventilation is essential in any 3D printer enclosure. Adequate airflow prevents the buildup of fumes produced by heated materials. It protects users from inhaling potentially harmful vapors. A good ventilation system also helps regulate the temperature inside the enclosure.

Maintaining Optimal Printing Temperatures

To achieve high-quality prints, it’s crucial to maintain optimal temperatures within the 3D printer enclosure. Materials such as ABS require a warm environment to prevent warping. Install a temperature control system to keep the interior at a consistent warmth. This will improve the quality of your prints and extend the lifespan of your 3D printer.

Safety Features for Your Enclosure

Ensuring safety is paramount when building a 3D printer enclosure. Special attention to fire and electrical safety can prevent accidents.

Fire Safety Measures

Fire safety is critical in 3D printing due to the high temperatures involved. Install a smoke detector inside the enclosure to alert you of potential fire risks. Keep a fire extinguisher nearby, designed to handle electrical fires. Choose materials that are fire-resistant, such as metal for the frame instead of wood. Avoid clutter and ensure the interior has ample space to prevent overheating. Regularly check for any frayed wires or electrical shorts that could lead to a fire.

Electrical Safety Precautions

Proper electrical safety is equally important. Ensure all wiring is up to code and insulated correctly. Use a power strip with surge protection to guard against power spikes. Organize cables to avoid tangling, and keep them away from heated parts. Ground your enclosure to prevent electrical shocks. Always unplug your 3D printer when performing maintenance inside the enclosure.

With these safety features in place, your 3D printer enclosure will not only be a bastion of innovation but also a beacon of security.

Enhancing your 3D Printer’s Performance with an Enclosure

Your 3D printer can do more with the right enclosure. We will look at how you can enhance performance.

Noise Reduction Techniques

Lowering noise levels is essential when your 3D printer is in a shared space. Use sound-dampening materials like foam or rubber for the enclosure’s walls. Make sure these materials can withstand the temperatures inside. Placing vibration-absorbing pads under the printer also helps reduce noise. An added benefit is less disturbance for those around you and more focus on your work.

Controlling Humidity Levels

Too much humidity affects print quality. It makes materials like PLA absorb moisture, which causes issues during printing. Integrate a dehumidifier into your enclosure to tackle this problem. Use silica gel packs if a dehumidifier isn’t an option. A hygrometer will help monitor humidity levels inside the enclosure. Keeping humidity in check ensures better prints and prolongs filament life.

Additional Accessories and Modifications for Enclosures

Beyond the basic structure, adding accessories and modifications can greatly enhance your 3D printer enclosure. These extras raise not just functionality but aesthetics too.

Lighting Options

Proper lighting in your 3D printer enclosure is not just for visibility. It allows for better monitoring of printing progress. LED strips are a popular choice. They are energy-efficient and can be placed to reduce shadows. Choose lighting that doesn’t add heat to the enclosure. This keeps temperature control consistent. Consider installing a switch outside the enclosure for easy control.

Access and Maintenance Easy Access Features

Design your enclosure with maintenance in mind. Hinged doors or removable panels give you quick access to the printer. This makes it easier to handle jams or maintenance without dismantling the whole enclosure. Magnetic catches or latches can secure doors while allowing for quick opening. Cable management systems keep wires tidy and out of the way. This not only looks cleaner but also prevents accidents during maintenance.

Conclusion: Maximizing Your 3D Printing Experience

As you complete your DIY 3D printer enclosure, keep your goals in focus. The efforts you’ve made offer great rewards. A well-built enclosure will safeguard your prints against environmental factors. It also raises safety levels, regulates noise, and maintains key temperatures for varied materials. Your printing sessions can now happen with less stress over unpredictable outcomes.

Crafting this space lets you handle a wider array of projects. By controlling the printing environment, you’re set to explore creative ideas with confidence. The enhancements and accessories mentioned will refine this setup even more. Remember to upkeep your enclosure, as this impacts both quality and safety.

A DIY 3D printer enclosure is more than a box—it’s a centerpiece for innovation in your workshop. As you invest in this project, so too does your expertise expand. With each print, you’ll see the benefits reflected in the quality and precision of your work. Happy printing!