Heat transfer printers have become an essential tool in the realms of custom printing and apparel design. They allow users to transfer images, graphics, and text onto fabrics efficiently and effectively. This technology caters to various industries, including fashion, sports, and promotional products. In this article, we will explore the functioning, types, advantages, and applications of heat transfer printers.

What is a Heat Transfer Printer?

A heat transfer printer uses heat to transfer a design onto a substrate, such as fabric, paper, or plastic. The process generally involves printing on a special transfer paper using a heat transfer printer, followed by applying heat and pressure to adhere the design to the chosen material. This method is favored for its versatility and simplicity in creating vibrant, high-quality designs.

The Basic Components

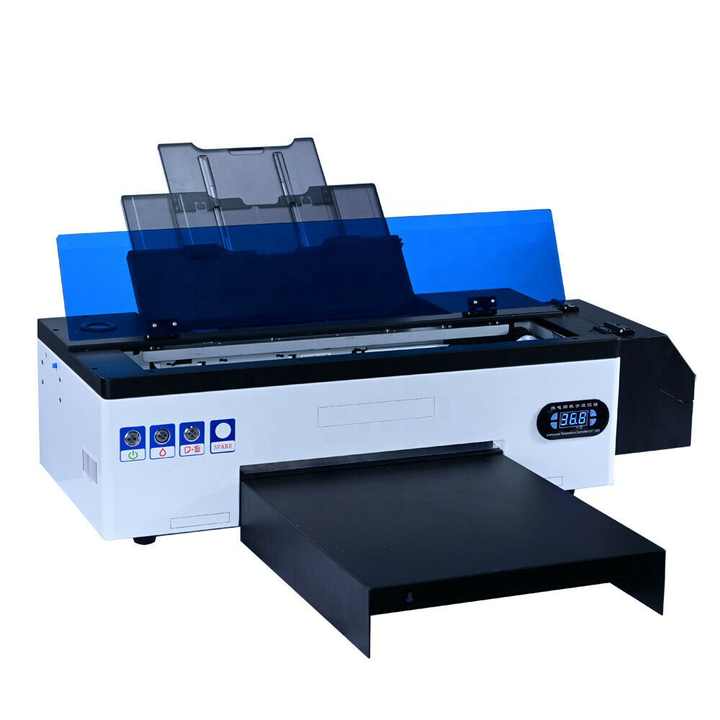

Heat transfer printers comprise several key components. Primarily, there is the printer itself, which often employs either inkjet or sublimation technology to produce the designs. The printer uses special inks suited for heat transfer, ensuring high color vibrancy and durability.

Next, there’s the transfer paper, an essential item that plays a crucial role in the transfer process. This paper is designed to withstand heat and allow ink to adhere properly. There are different types of transfer papers designed for different fabrics. For instance, some papers work better on light materials, while others are intended for dark fabrics.

Finally, a heat press machine is a vital piece of equipment used in the process. This machine applies the necessary heat and pressure during the transfer, allowing the ink to bond securely with the substrate. The combination of these components is what makes heat transfer printers a popular choice among crafters and businesses alike.

How Does Heat Transfer Printing Work?

Heat transfer printing involves a sequence of steps that are simple yet effective. Understanding this process can help users appreciate its efficiency and practical applications.

The Printing Stage

The first step is printing the desired image onto transfer paper. Users typically design the graphics using graphic design software. Once satisfied, they can print the design using a heat transfer printer. It’s crucial to choose the right type of ink and transfer paper based on the fabric’s nature. For instance, sublimation printers are ideal for polyester fabrics as they produce vivid colors that penetrate the material.

The Transfer Process

After printing, the next step is to apply heat and pressure. The transfer paper is placed on the substrate in the heat press machine. The machine is then set to the appropriate temperature, time, and pressure settings. Once activated, the heat press securely attaches the design to the fabric.

During this phase, the heat causes the ink to vaporize and bond with the fibers of the material, ensuring that the design becomes a permanent part of the fabric. This method is efficient as it allows for multiple items to be processed in a short time frame, making it suitable for both small and large production runs.

Types of Heat Transfer Printers

When diving into the world of heat transfer printing, it’s essential to understand the different types of printers available. Each type caters to particular needs and preferences.

Inkjet Printers

Inkjet printers are one of the most common types used for heat transfer printing. They are user-friendly and relatively affordable. These printers use water-based inks, which makes them suitable for various types of transfer papers. Inkjet printers can produce vibrant and detailed images, making them popular among small businesses and individuals.

However, it’s worth noting that inkjet-printed transfers may not be as durable as other options. Over time, washing and wear can cause them to fade or crack. Users must follow proper washing instructions to maintain the quality of their designs.

Dye Sublimation Printers

Dye sublimation printers are another popular choice, mainly for their ability to produce high-quality images. These printers use specialized inks that turn into gas when heated. The gas then penetrates the fibers of the material, resulting in a vibrant and durable image.

Dye sublimation works best on polyester or polymer-coated substrates. This method is perfect for sports apparel and promotional items that require bold and lasting colors. While the initial investment may be higher, the long-term durability and quality of the prints often justify the cost for many businesses.

Advantages of Heat Transfer Printing

Heat transfer printing offers numerous benefits that contribute to its rising popularity in various fields. Understanding these advantages can help users make informed decisions when choosing a printing method.

Versatility

One of the most notable advantages is versatility. Heat transfer printers can print on numerous substrates, including cotton, polyester, blends, and even hard surfaces like ceramics and metals. This versatility makes it easy to switch between different projects without needing extensive equipment adjustments.

Moreover, users can create complex designs with multiple colors, gradients, and intricate details. This flexibility allows for infinite creative possibilities, appealing to both hobbyists and professionals.

Cost-Effectiveness

Another significant advantage is cost-effectiveness. Heat transfer printing is often more affordable than traditional screen printing, especially for small runs. The need for screens and setup time in screen printing can be prohibitive for smaller projects or businesses. With heat transfer printing, users can produce short runs without high initial costs.

Additionally, as a business tool, it allows for easy customization of products. Businesses can quickly implement changes or add personalization features, catering to customer demands efficiently.

Applications of Heat Transfer Printers

Heat transfer printers find applications across various industries, exemplifying their versatility and efficiency. From fashion design to promotional marketing, heat transfer printing plays a crucial role in many sectors.

Fashion Industry

In the fashion industry, heat transfer printing is instrumental in creating custom apparel. Designers can showcase their creativity by printing unique graphics, text, and designs on garments. Items like T-shirts, sweatshirts, and hats often utilize this printing technology.

Moreover, fashion events, sports teams, and organizations regularly employ heat transfer printing for creating uniforms and promotional items. The process is also effective in producing limited-edition collections, as it offers quick turnaround times and affordable options.

Promotional Products

Heat transfer printing is heavily used for promotional products, including bags, mugs, and keychains. Businesses often give away these items for marketing purposes. The ability to personalize these products with logos and slogans enhances brand visibility.

Companies can create eye-catching promotional material targeting their audience effectively. Since heat transfer printing is quick and cost-effective, businesses can frequently refresh their product offerings based on market trends.

Benefits of Using Heat Transfer Printers in Small Businesses

For small businesses and startups, heat transfer printing is an accessible option with numerous benefits. Entrepreneurs can utilize this method to grow their brands and reach their target audiences effectively.

Customization Opportunities

Customization plays a vital role in today’s market. Consumers often seek unique products tailored to their preferences. Heat transfer printing allows small businesses to produce customized items in small quantities. Whether it’s a one-off T-shirt for a special event or personalized bags for a local market, the opportunities are endless.

Additionally, as a small business grows, it can easily scale its heat transfer printing capabilities. This adaptability ensures that as demand increases, businesses can meet their customers’ needs without substantial investments.

Low Startup Costs

Starting a printing business using heat transfer technology requires minimal initial investment. Compared to other printing methods like screen printing, which demands more equipment and setup, heat transfer printing allows for quick entry into the market. With just a printer, heat press, and transfer paper, entrepreneurs can start their journey.

Furthermore, operating costs remain low, making it easier to maintain sustainable profits. This financial flexibility is often appealing to small business owners looking to establish their presence without taking on excessive risk.

Considerations When Choosing Heat Transfer Printers

While heat transfer printers offer numerous benefits, it’s essential to approach purchasing one with careful consideration. There are key factors that potential buyers should evaluate before making a decision.

Ink Quality

The quality of the ink used is vital for producing high-quality prints. Users should opt for printers that support high-quality inks suitable for heat transfer. The durability and brightness of the prints often depend on the ink’s formulation.

Additionally, relying on reputable brands can ensure that the inks are specifically designed for heat transfer applications. This focus on quality will yield better results and enhance the longevity of the printed designs.

User-Friendliness

Another crucial aspect is user-friendliness. In a busy environment, especially for small businesses, it’s important to choose a printer that is easy to operate. A printer with an intuitive interface can save time and reduce learning curves.

Moreover, users should consider whether the software required for design and printing is accessible and straightforward. A smooth operational flow contributes significantly to efficiency and productivity in a business setting.

Ensuring Quality Outputs

Producing high-quality prints consistently requires attention to detail. Users must stay aware of several factors that contribute to the overall output quality.

Preparing the Design

Before printing, it’s important to ensure that the design is well-prepared. This involves selecting the correct size and resolution, ensuring that the colors are accurate, and double-checking for any errors. High-resolution designs produce better prints, ensuring that fine details are crisp and clear.

Additionally, utilizing color profiles specific to heat transfer can enhance color accuracy. Professionals often recommend these preparations for achieving the best results in the final output.

Printing Settings

Proper printer settings are paramount for quality outputs. Users should optimize settings such as temperature, print speed, and pressure based on the substrate type. Each material behaves differently, and adjusting the heat press accordingly ensures the best adhesion and color vibrancy.

Taking the time to conduct test prints can also help in determining the optimal settings for specific projects. This proactive approach minimizes waste and enhances overall production efficiency.

Maintenance and Care for Heat Transfer Printers

Regular maintenance is essential to ensure the longevity and performance of heat transfer printers. Keeping the equipment in good condition helps users avoid costly repairs and downtimes.

Regular Cleaning

Cleaning the printer regularly is crucial to prevent clogs and maintain output quality. Dust and residue can accumulate over time, leading to imperfections in prints. Users should follow manufacturer instructions for cleaning the print heads and nozzles.

Additionally, regularly inspecting and cleaning the heat press plates can ensure even heat distribution during transfers. This step prevents uneven transfers that can compromise the quality of the prints.

Updating Software and Firmware

Keeping the software and firmware updated is another important maintenance step. Software updates often include improvements in functionality and performance. Staying current with updates can enhance printing capabilities, giving users access to new features and options.

Moreover, keeping the design software updated ensures compatibility with various file formats, making it easier to create high-quality designs without technical hitches.

Conclusion

Heat transfer printers represent a versatile, efficient, and cost-effective option for custom printing. Their ease of use, coupled with the ability to create vibrant designs, makes them ideal for a wide range of applications. From the fashion industry to promotional products, the potential is vast for both small businesses and large enterprises.

By understanding the basic components, operation, types, and advantages of heat transfer printers, users can make informed decisions. Careful consideration of quality outputs, maintenance, and operational needs further enhances the experience. Heat transfer printers not only ignite creativity but also pave the way for successful business ventures. As technology moves forward, these printers will continue to play a significant role in design and printing, fostering innovation and expansion across numerous industries.