Direct-to-Film (DTF) transfer printing is revolutionizing the textile printing industry. It offers extraordinary flexibility, vibrant colors, and durability. This article will explore the various aspects of DTF transfer printers, highlighting their benefits, features, and considerations.

Introduction to DTF Transfer Printing

What is DTF Transfer Printing?

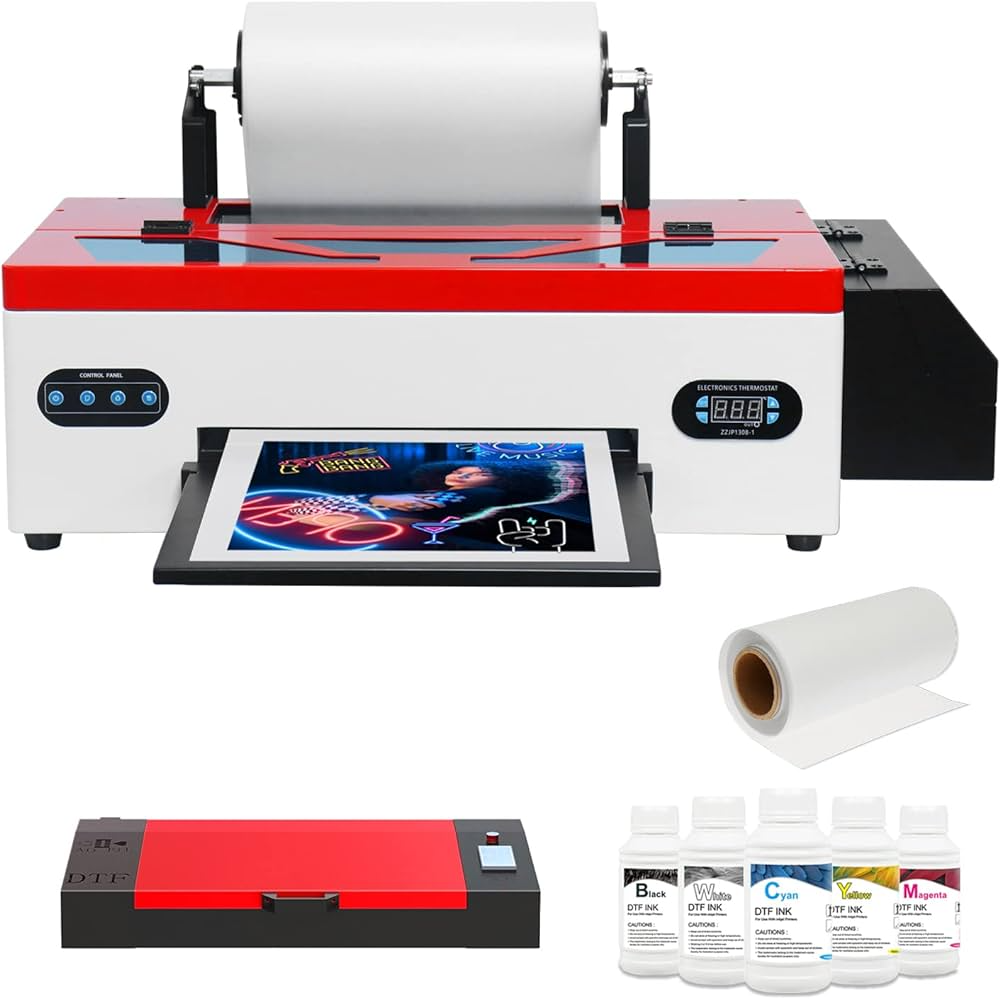

DTF transfer printing is a method where designs are printed directly onto a special film, which is then transferred onto fabric. Unlike other printing methods, DTF does not require pre-treatment of fabrics. The process is straightforward: print the design onto a film, sprinkle adhesive powder, heat press the film onto the fabric, and peel off the film. This method is gaining popularity due to its ease of use and versatility.

Growth of DTF Printing Technology

The DTF printing technology has emerged as a strong competitor in the textile printing market. It offers unique advantages over traditional methods like screen printing and Direct-to-Garment (DTG) printing. The growing demand for custom apparel, coupled with advancements in printing technology, has accelerated the adoption of DTF printers. Businesses and hobbyists are increasingly turning to this technology for its reliability and efficiency.

Design and Build Quality of DTF Printers

Robust Construction

DTF printers are known for their robust construction. Manufacturers use high-quality materials to ensure durability and longevity. The printer’s frame is usually made from reinforced metal, providing stability during operation. The components are designed to withstand continuous use, making DTF printers an excellent investment for businesses.

User-Friendly Design

Despite their advanced capabilities, DTF printers are designed with the user in mind. The layout is intuitive, with accessible controls and easy-to-follow instructions. The touchscreen interface allows users to input settings, monitor the printing process, and make adjustments effortlessly. The design also includes safety features like automatic shutdown and temperature control, ensuring a smooth and safe printing experience.

Performance and Print Quality

Vibrant and Durable Prints

One of the standout features of DTF printers is their ability to produce vibrant and durable prints. The color output is exceptional, with a wide gamut that captures intricate details and gradients effectively. The prints are also highly durable, withstanding multiple washes without fading or cracking. This durability makes DTF prints suitable for various applications, including sportswear, custom apparel, and promotional items.

High Efficiency

DTF printers offer high efficiency, making them suitable for both small and large-scale production. The printing speed is impressive, allowing for quick turnaround times. The printers also support continuous printing, reducing downtime and increasing productivity. This efficiency is a significant advantage for businesses looking to meet high demand and tight deadlines.

Versatility and Applications

Wide Range of Compatible Fabrics

DTF printing is incredibly versatile, supporting a wide range of fabrics. This flexibility allows businesses to experiment with various materials, expanding their product offerings. Common fabrics used with DTF printing include cotton, polyester, nylon, and blends. The method’s adaptability ensures that the print adheres well to each fabric type, maintaining vivid colors and sharp details.

Diverse Applications

The applications of DTF printing are diverse, catering to different industries and needs. Custom apparel businesses benefit greatly from this technology, offering unique designs and personalized items. The sportswear industry relies on DTF printing for durable and vibrant uniforms. Promotional products, such as tote bags and caps, also leverage DTF printing for eye-catching designs. The versatility of DTF printers makes them suitable for any industry requiring high-quality and durable prints.

Cost-Effectiveness and ROI

Lower Initial Investment

One of the appealing aspects of DTF printers is their cost-effectiveness. The initial investment is relatively lower compared to other printing technologies. This affordability makes it accessible for small businesses and startups. Moreover, the ongoing operational costs are manageable, with reasonably priced consumables and minimal maintenance requirements.

High Return on Investment

Despite the lower initial investment, the return on investment (ROI) for DTF printers is high. This technology allows businesses to offer a wide range of products, attracting more customers and increasing revenue. The high efficiency and low operational costs contribute to quick recoupment of the initial investment. Businesses also benefit from the ability to produce high-quality prints in-house, reducing reliance on external printing services and saving costs in the long run.

Maintenance and Support

Simple Maintenance

Maintaining a DTF printer is straightforward. Regular cleaning and occasional part replacements ensure the printer remains in optimal condition. The design allows easy access to critical components, simplifying the maintenance process. Manufacturers provide detailed guides and tutorials, helping users perform maintenance tasks without professional assistance. This simplicity extends the printer’s life and ensures consistent print quality.

Reliable Customer Support

Manufacturers of DTF printers offer reliable customer support, addressing any issues promptly. Support is available through various channels, including phone, email, and live chat. Users can also access online resources, such as forums and FAQs, to troubleshoot common problems. The robust customer support network ensures that users can rely on their DTF printer for continuous operation, minimizing downtime and maximizing productivity.

Environmental Impact

Eco-Friendly Inks

DTF printers use eco-friendly inks, reducing the environmental impact. These inks are water-based and free from harmful chemicals, making them safe for use. The eco-friendly nature of the inks aligns with the growing demand for sustainable practices in the textile industry. Businesses using DTF printers can market their products as environmentally conscious, appealing to eco-aware consumers.

Energy Efficiency

DTF printers are designed to be energy efficient. They consume less power compared to traditional printing methods, reducing energy costs and environmental footprint. The printers also include features like automatic shutdown and energy-saving modes, further enhancing their efficiency. This energy efficiency contributes to the overall sustainability of the DTF printing process.

Challenges and Considerations

Learning Curve

One of the challenges associated with DTF printing is the learning curve. Although the printers are user-friendly, mastering the workflow requires practice. Users need to familiarize themselves with the software, understand the optimal settings for different fabrics, and learn the best practices for film transfer. This learning curve can be challenging for beginners, but with time and experience, users can achieve excellent results.

Print Head Maintenance

Print head maintenance is crucial for the proper functioning of DTF printers. The print heads can clog if not cleaned regularly, affecting the print quality. Users need to follow a maintenance schedule, performing routine cleanings to prevent clogs. While this maintenance task is straightforward, it requires diligence and consistency. Neglecting print head maintenance can lead to costly repairs and downtime.

Adhesive Powder Handling

Handling adhesive powder is another consideration for DTF printing. The powder needs to be applied evenly to ensure a proper transfer. Inconsistent application can result in poor adhesion, affecting the print’s durability. Users need to follow the recommended procedures for applying and curing the adhesive powder. Proper handling of the adhesive powder ensures that the prints adhere well and remain durable.

Future of DTF Printing

Technological Advancements

The future of DTF printing is promising, with ongoing technological advancements. Researchers and manufacturers are continuously working on improving print quality, speed, and efficiency. New inks and adhesive powders are being developed to enhance the printing process. These advancements ensure that DTF printing remains at the forefront of textile printing technology, offering even better performance and reliability.

Growing Adoption

The adoption of DTF printing is growing across various industries. The technology’s versatility and cost-effectiveness make it appealing for businesses of all sizes. As more businesses recognize the benefits of DTF printing, the demand for DTF printers is expected to increase. This growing adoption will further drive innovation and advancements in DTF printing technology, ensuring its continued relevance and evolution.

Conclusion

Final Thoughts on DTF Transfer Printers

DTF transfer printers are transforming the textile printing industry. Their ability to produce vibrant, durable prints on a wide range of fabrics makes them an invaluable tool for businesses and hobbyists alike. The robust construction, user-friendly design, high efficiency, and versatile applications make DTF printers a worthwhile investment. Despite some challenges, the overall benefits and cost-effectiveness of DTF printing outweigh the considerations.

In conclusion, DTF transfer printers offer numerous advantages, making them a standout option in the textile printing market. The combination of affordability, performance, and versatility ensures that businesses can meet the growing demand for custom apparel and promotional products. As technology continues to advance, DTF printers will remain a significant player in the textile printing industry, offering innovative solutions and unparalleled quality. Whether you are a small business owner, a startup, or a hobbyist, investing in a DTF transfer printer is a smart choice that will pay off in the long run.