Dot matrix printers have been fundamental in the evolution of modern printing technology. Despite the advent of more advanced printers, their unique attributes and capabilities sustain their relevance. This article delves into the various facets of dot matrix printers, exploring their history, functionality, applications, and why they remain indispensable in certain fields.

The Origin and Evolution of Dot Matrix Printers

Dot matrix printers appeared in the early 1970s. Their development marked a significant leap in printing technology. Before dot matrix, printers were generally bulky and expensive, limiting accessibility for both personal and business use. Dot matrix printers changed this by providing a less costly yet highly reliable alternative.

The earliest versions of dot matrix printers capitalized on a combination of mechanical precision and electrical efficiency. These printers used a pin or wire head striking an ink-soaked ribbon to create an impression on paper. This method represented an evolution from the typewriter’s single-character approach, offering greater versatility. Each letter, number, or symbol created with a dot matrix printer comprised a pattern of small dots. This generated complex characters and images from a series of simple processes.

Over the years, dot matrix printers have undergone significant improvements. Manufacturers have refined the design, increasing the number of pins in the print head to enhance print quality. Innovations such as color printing, multipart forms capability, and higher endurance for continuous printing have further cemented their place in specific market niches.

The Role of Impact Printing in Dot Matrix Technology

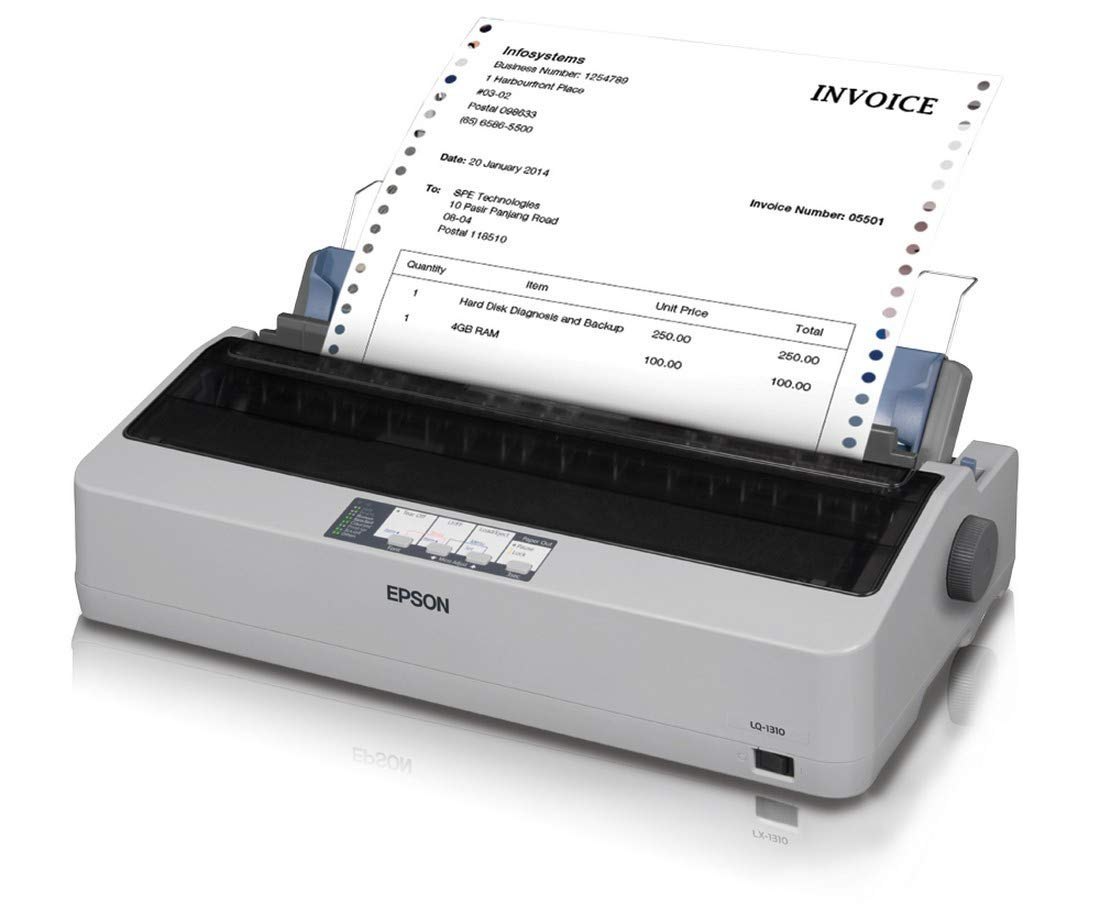

One distinguishing feature of dot matrix printers is their reliance on impact printing. In contrast to the non-impact printing techniques used in inkjet and laser printers, impact printing involves creating characters by physically striking an ink ribbon against the paper. This gives dot matrix printers a unique advantage—they can print on multi-part forms, carbon copies, and even certain types of labels. Businesses dealing with shipping labels, invoices, and receipts still prefer dot matrix printers for their ability to produce multiple copies in a single print cycle.

Impact printing is robust, durable, and reliable. The mechanical action involved can handle varied paper types and withstand the rigors of high-volume tasks. Although slower and noisier compared to modern non-impact printers, the dot matrix’s impact printing provides consistency, particularly where precision and durability are crucial.

The Inner Workings: How Dot Matrix Printers Operate

To understand the value of dot matrix printers, one must appreciate their intricate operational mechanics. A typical dot matrix printer consists of several key components: the print head, platen (or roller), ribbon, and the paper feed mechanism. The magic lies in the precise coordination among these parts.

Print Head and Pins

The print head in a dot matrix printer houses several tiny pins arranged in arrays, usually in multiples of 9 or 24. When printing, these pins strike an inked ribbon, transferring the ink onto the paper in a series of closely packed dots. The arrangement and number of pins directly affect print quality and speed. The higher the number of pins, the finer the print resolution. This is because more pins can cover an area more thoroughly with overlapping dots, creating smoother lines and curves.

Paper Feed Mechanism

The paper feed mechanism in dot matrix printers accommodates continuous paper rolls and single-sheet feeds. In continuous feed mode, perforated edges on the paper strip interact with a tractor feed mechanism, ensuring even and consistent advancement of paper. This ability to handle continuous paper makes dot matrix printers ideal for long, uninterrupted print jobs. Moreover, special features like tear-off functionality enable easy detachment of printed documents from the continuous feed.

The Ink Ribbon

The ink ribbon is a consumable component that must be replaced periodically. However, a single ribbon can print many pages before depletion, making dot matrix printers economical regarding ink usage. Unlike non-impact printers where cartridges can be relatively expensive, the ribbon used in dot matrix printers is simple and cost-effective.

Applications and Practical Uses of Dot Matrix Printers

Dot matrix printers have found a niche in certain business sectors due to their durability, reliability, and cost-effectiveness. While newer kinds of printers have dominated the market, the dot matrix remains significant in specific environments.

Warehousing and Logistics

Warehouses, for example, frequently use dot matrix printers to produce multi-part forms. These forms, often containing critical shipping information, are printed in multiple copies for different stakeholders in the supply chain. Dot matrix printers excel in this scenario due to their ability to produce legible multi-part documents quickly and efficiently.

Industrial Settings

In industrial settings, durability and longevity are paramount. Dot matrix printers can withstand harsh environments, including extreme temperatures, dust, and vibrations. They continue to operate without fail in conditions where other types of printers might struggle. Industrial plants often use dot matrix printers for logging machine data, printing labels for products, or generating operation reports.

Government and Financial Institutions

Government offices and financial institutions sometimes prioritize the longevity and verifiability of printed records. Legal documents, financial reports, and tax records created via dot matrix printers offer robustness and longevity, ensuring that these prints can be authenticated and preserved over long periods.

POS Systems

In retail, point-of-sale (POS) systems often incorporate dot matrix printers for receipt printing. Their ability to manage extensive print cycles without frequent maintenance makes them an excellent option for environments where the volume of printing can be very high daily.

Advantages and Limitations of Dot Matrix Printers

Despite the dominance of inkjet and laser printers, dot matrix printers maintain a unique position, balancing advantages and limitations that make them suitable for specific uses.

Advantages

- Durability and Reliability: Dot matrix printers’ robust construction allows them to function effectively in environments where other printers might fail.

- Cost-Effectiveness: The initial purchase and ongoing operational costs, including ink ribbon replacements, are lower compared to inkjet and laser printers.

- Multi-Part Forms: Their ability to print on multi-part forms is unmatched, making them essential for tasks that require duplicates or triplicates.

- Flexibility: They can handle a range of media types, sizes, and thicknesses, from regular paper to thicker labels and envelopes.

- Long Print Runs: Ideal for high-volume, continuous print jobs without frequent interruptions or maintenance.

Limitations

- Print Quality: Dot matrix printers lag behind in print quality compared to modern inkjet and laser printers, especially for producing high-resolution images and graphics.

- Speed: They are generally slower than modern printers, which can be a drawback in environments requiring rapid printouts.

- Noise: The impact-based print mechanism produces significant noise, which can be a distraction in quiet office environments.

- Technology Lag: They represent an older technology that hasn’t seen significant innovation compared to their inkjet and laser counterparts.

Future Prospects and Technological Advancements

The future of dot matrix printers is likely to remain niche but secure due to their unique capabilities. While we may not see a revolutionary transformation in dot matrix technology, incremental improvements can be expected, focusing on enhancing efficiency, speed, and environmental sustainability.

Sustainability and Environmental Impact

One area of potential advancement is in producing more environmentally friendly inks and ribbons. Reducing the environmental impact of consumables can align with broader industry trends towards sustainability. Implementing energy-saving features, such as low-power modes, could also make these printers more eco-friendly.

Interoperability in Modern Systems

Increasing interoperability with contemporary IT systems and software could help dot matrix printers stay relevant. Ensuring easy integration with modern network environments and offering support for newer communication protocols will likely be essential for maintaining usability in industrial and commercial settings.

Enhanced Durability and Reliability

Continual improvements in materials and construction methods can further enhance the printers’ durability and reliability. Innovations in wear-resistant components and advanced cooling solutions can extend the lifespan of these machines even further, ensuring they remain a viable option for demanding applications.

Conclusion: The Enduring Relevance of Dot Matrix Printers

Dot matrix printers have stood the test of time, adapting to and surviving drastic changes in printing technology trends. Their reliability, cost-effectiveness, and unique capabilities, such as impact printing and multi-part forms, ensure their continued utility in specific industries. While their role in general office settings may have diminished, they remain indispensable in sectors requiring durable and reliable printing solutions.

Despite their limitations in terms of noise, speed, and print quality, the dot matrix printer’s advantages hold substantial value. Continuous yet incremental improvements are likely to keep them relevant even as newer technologies emerge. Therefore, understanding the intricate workings and practical applications of dot matrix printers is crucial for appreciating their lasting significance in the world of printing technology.