In an era where technology continuously reshapes industries, UV printing stands as a testament to the fusion of innovation and creativity. This advanced printing method, harnessing the power of ultraviolet light, has disrupted traditional printing practices, offering unparalleled speed, versatility, and environmental friendliness. This in-depth exploration delves into the mechanics, applications, benefits, and future prospects of UV printers, painting a vivid picture of how they are transforming the printing landscape.

The Fundamentals of UV Printing Technology

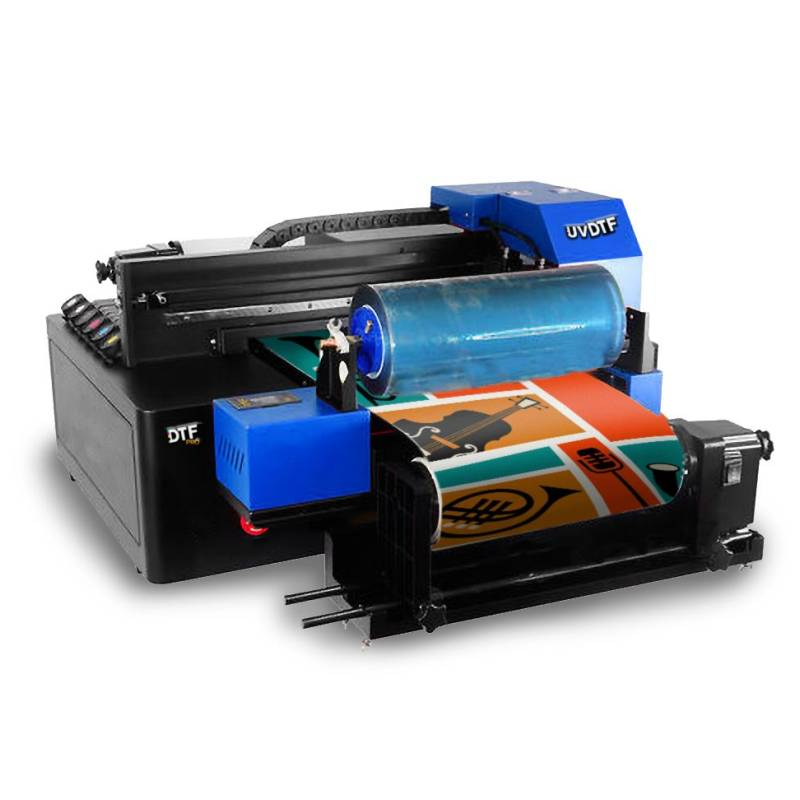

At the heart of UV printing lies a sophisticated process that diverges from conventional inkjet methods. Instead of using solvent-based inks that require time to dry and release VOCs (volatile organic compounds), UV printers employ special inks that solidify under UV light exposure. This instant curing mechanism not only accelerates the printing process but also eliminates the need for drying time, significantly reducing production cycles.

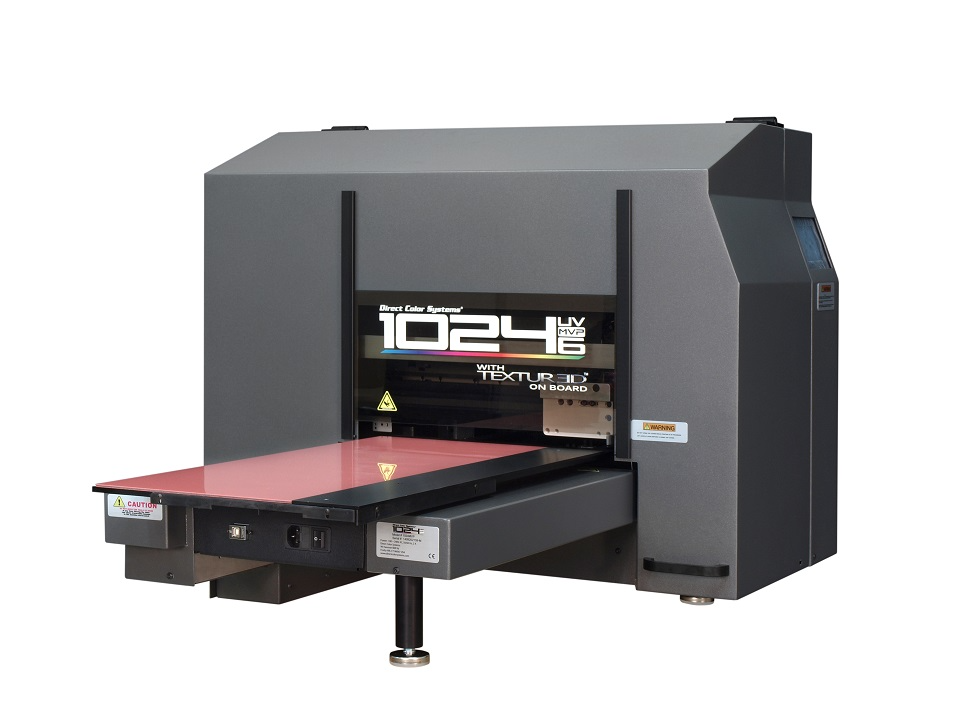

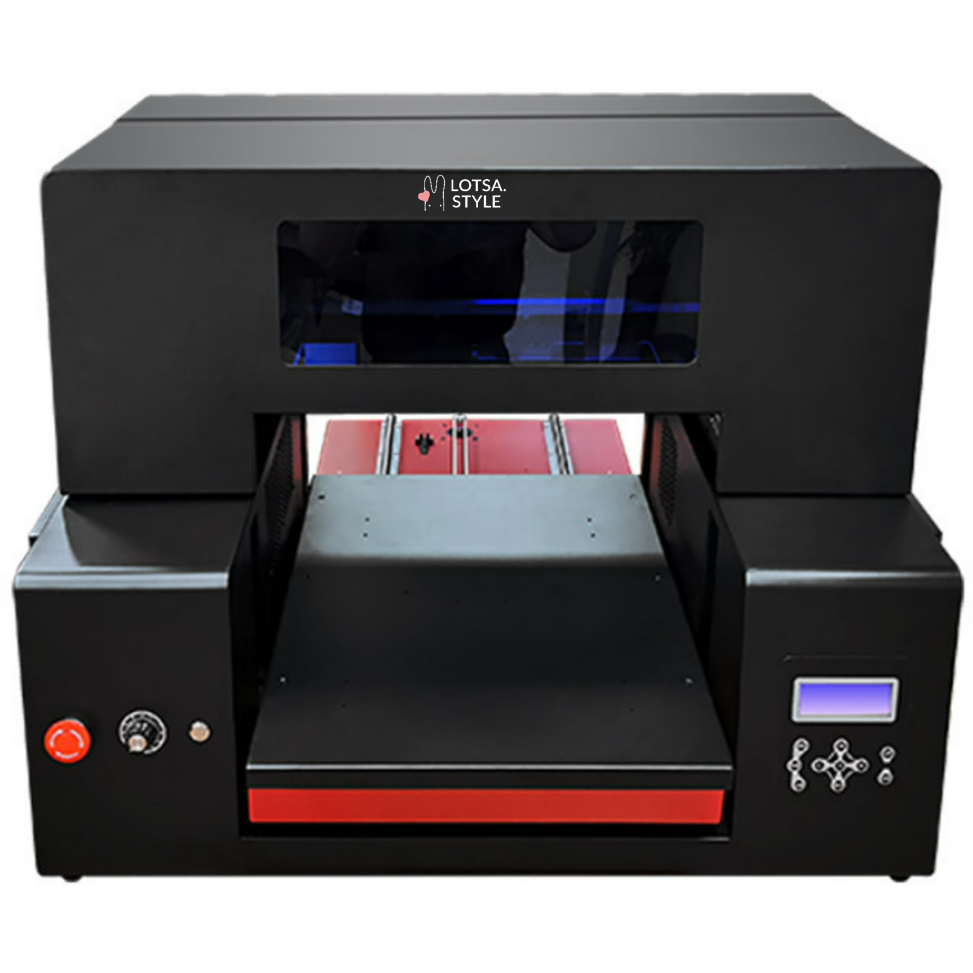

The core components of a UV printer include high-intensity UV lamps or LED arrays, which emit UV radiation to cure the ink immediately after it is deposited onto the substrate. These inks consist of photoinitiators, pigments, and resins, which, when exposed to UV light, undergo a chemical reaction, transforming from liquid to solid state within seconds.

Versatility Unleashed: Materials and Applications

One of the defining features of UV printing is its adaptability to a vast array of substrates. From rigid materials like glass, metal, and acrylic to flexible media such as PVC, textiles, and even wood, UV printers open up a world of possibilities. This flexibility expands creative horizons, enabling printers to produce high-quality outputs on non-traditional surfaces, thereby catering to diverse sectors including signage, packaging, interior decoration, and personalized gifts.

Quality and Durability Redefined

UV-printed products boast exceptional color vibrancy and durability. The instant curing process locks in the ink, creating a scratch-resistant and fade-proof finish. This characteristic is particularly valuable for outdoor applications, where prints are exposed to harsh weather conditions. Moreover, UV inks offer better resistance to chemicals and abrasion, ensuring longevity and maintaining the integrity of the printed images.

Efficiency and Environmental Footprint

Efficiency is another hallmark of UV printing technology. The elimination of drying time streamlines production, allowing for faster turnaround and increased throughput. This translates into reduced energy consumption and lower operational costs compared to traditional methods that require additional heat or extended drying periods. Furthermore, since UV inks do not emit VOCs, they contribute to a safer working environment and align with global trends towards sustainability.

Cost-Effectiveness and Return on Investment

While the initial investment in UV printing equipment may seem substantial, the long-term benefits often outweigh the costs. Reduced material waste, lower energy usage, and faster production cycles contribute to a quicker return on investment. Additionally, the ability to print directly onto a variety of substrates eliminates the need for additional printing plates or labels, further reducing expenses and broadening profit margins.

The Creative Frontier: Personalization and Customization

Personalization and customization are driving forces in today’s consumer market. UV printers excel in this arena, offering on-demand printing capabilities that cater to individual preferences. Whether it’s custom packaging, personalized gifts, or unique interior designs, UV printing enables businesses to create tailored products quickly and economically, fostering stronger customer connections and enhancing brand loyalty.

Future Perspectives and Technological Advancements

As technology evolves, so too does the potential of UV printing. Research is ongoing to develop more efficient UV lamps and LED systems, improving energy efficiency and reducing curing times even further. Innovations in ink technology promise enhanced color gamuts and even greater adhesion to challenging substrates. Furthermore, the integration of smart technologies, such as IoT and AI, into UV printing workflows is poised to optimize production, predict maintenance needs, and facilitate remote monitoring, making operations more streamlined and efficient.

Challenges and Considerations

UV printers, also known as UV-curing printers, are a type of digital printing technology that uses ultraviolet (UV) light to instantly dry or cure ink onto a wide range of substrates. This technology offers several advantages over traditional printing methods, including faster drying times, ability to print on various materials, and improved durability of the printed products. However, like any technology, UV printers come with their own set of challenges and considerations. Here are some key points to consider:

Initial Investment Cost

One of the primary challenges is the relatively high upfront cost associated with purchasing a UV printer compared to conventional printers. The technology involves specialized components such as UV lamps, which can increase the overall cost.

Running Costs

While UV inks can be more expensive than traditional solvent or aqueous inks, they often provide cost savings in the long run due to reduced waste and increased efficiency. However, factors such as the cost of replacing UV lamps and maintenance should also be considered.

Substrate Compatibility

Although UV printers are versatile and can print on many surfaces, not all materials are suitable for UV curing. Some sensitive materials may react negatively to the intense UV light or the chemical composition of the inks. It’s essential to test materials beforehand to ensure compatibility.

Ink Curing Efficiency

Achieving a complete and consistent cure is crucial for print quality and durability. Factors like ink layer thickness, substrate porosity, and UV lamp intensity can affect the curing process, requiring careful calibration and monitoring.

Environmental Impact

While UV inks are generally considered more environmentally friendly than solvent-based inks because they emit fewer volatile organic compounds (VOCs), the disposal of UV lamps and potential release of mercury during breakage pose environmental concerns. Proper handling and recycling practices are necessary.

Maintenance and Training

UV printers require specialized knowledge for operation and maintenance. Staff needs training on handling the equipment, managing ink systems, and understanding the unique properties of UV inks and curing processes.

Health and Safety

Exposure to UV light can be harmful to operators, necessitating the use of personal protective equipment (PPE), such as gloves and goggles. Adequate ventilation is also important to manage potential fumes from the curing process.

Color Matching and Consistency

Achieving accurate and consistent color reproduction can be challenging with UV printing, especially when transitioning from traditional printing methods. Factors like ink chemistry, curing settings, and substrate interaction can all impact color output.

Innovation and Technological Advancements

The UV printing industry is continually evolving, with new technologies and improvements being introduced regularly. Staying up-to-date with these advancements can be a challenge, but is necessary to remain competitive and offer the best possible service to clients.

Addressing these challenges requires a combination of careful planning, ongoing training, and investment in the right technology and resources. Despite these considerations, UV printing offers significant benefits, making it an attractive option for businesses looking to expand their printing capabilities and offer innovative, high-quality print services.

Conclusion: A Bright Future for UV Printing

UV printing represents a quantum leap in the evolution of printing technology. Its unique combination of speed, versatility, eco-friendliness, and superior output quality positions it as a game-changer across various industries. As advancements continue to push the boundaries of what’s possible, UV printing is set to play an increasingly pivotal role in meeting the growing demands for customization, efficiency, and sustainability. In this digital age, where innovation is the cornerstone of progress, UV printing stands as a beacon, illuminating a path towards a more vibrant, efficient, and environmentally conscious future in the realm of visual communication.