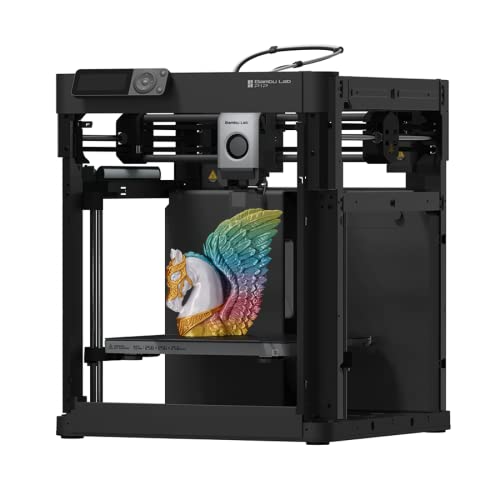

In the ever-evolving landscape of manufacturing and design, 3D printing has emerged as a game-changer, offering unprecedented possibilities for creativity, customization, and efficiency. Among the myriad of 3D printers available in the market, the Bambu 3D Printer stands out as a beacon of innovation and sustainability. This comprehensive exploration delves into the core features, applications, and impact of this remarkable technology, surpassing the traditional boundaries of 3D printing.

A Green Revolution: Sustainability at its Core

The Bambu 3D Printer distinguishes itself not just by its technological prowess but also through its commitment to environmental sustainability. Unlike conventional 3D printers that primarily rely on plastics and synthetic materials, the Bambu utilizes a unique blend of bamboo-based filament, a renewable resource known for its strength, versatility, and eco-friendliness. By integrating natural fibers into the printing process, it significantly reduces carbon footprint while maintaining structural integrity and aesthetic appeal.

Precision Engineering: Crafting Perfection

At the heart of the Bambu 3D Printer lies state-of-the-art engineering that ensures precision and accuracy in every print. Equipped with high-resolution printing capabilities, it can produce intricate designs with layers as thin as 50 microns, enabling the creation of detailed models, prototypes, and functional parts with unparalleled smoothness and finish. Its advanced extrusion system maintains consistent flow and temperature control, preventing warping and ensuring dimensional accuracy, even in complex geometries.

Versatility Unleashed: From Art to Industry

One of the most compelling aspects of the Bambu 3D Printer is its versatility. It transcends the boundaries of traditional manufacturing, catering to diverse sectors including architecture, product design, fashion, medical prosthetics, and even aerospace. Architects can print scale models of their designs, fashion designers can create custom accessories, while medical professionals leverage its capabilities to fabricate precise prosthetic limbs or surgical models. The Bambu’s adaptability ensures that the only limit to its applications is the user’s imagination.

User-Friendly Interface: Simplifying Complexity

Understanding the need for accessibility, the Bambu 3D Printer boasts a user-friendly interface designed to streamline the printing process for both novices and experts alike. With intuitive software, users can easily upload designs, adjust settings, and monitor the printing progress remotely. The software supports a wide range of 3D modeling formats, making it compatible with various design tools. Additionally, built-in tutorials and a comprehensive online community provide continuous support, fostering a collaborative environment where users can learn, share ideas, and troubleshoot together.

Efficiency Redefined: Speed Meets Cost-Effectiveness

The Bambu 3D Printer optimizes production speed without compromising quality, making it a cost-effective solution for businesses and individuals alike. Its large build volume allows for the creation of multiple objects in a single print run, reducing per-unit costs and time-to-market. Moreover, the use of sustainable bamboo filaments often results in lower material costs compared to traditional plastic alternatives. This combination of speed and affordability makes the Bambu an attractive option for prototyping, small-scale manufacturing, and personalized production runs.

Innovation Through Integration: Expanding the Horizon

Recognizing the potential of integration, the Bambu 3D Printer is designed to work seamlessly with emerging technologies like AI and IoT. This integration enables real-time monitoring of the printing process, predictive maintenance, and even automatic adjustment of settings based on environmental factors or previous performance data. By embracing these advancements, the Bambu not only enhances its operational efficiency but also paves the way for smart, interconnected manufacturing systems of the future.

Empowering Education and Creativity

Beyond industrial applications, the Bambu 3D Printer plays a pivotal role in education, fostering hands-on learning experiences that promote critical thinking, problem-solving, and creativity. Students across various disciplines can witness their designs come to life, from physics experiments to architectural models, enhancing their understanding of spatial concepts and design principles. This educational tool encourages a new generation of thinkers and makers equipped to tackle real-world challenges using cutting-edge technology.

Challenges and the Road Ahead

The Bambu 3D Printer, as an imagined innovative and eco-friendly printing technology using bamboo-based materials, faces several challenges and opportunities on its path to becoming a mainstream solution in the additive manufacturing industry. Here are some of the key challenges and the road ahead for such a venture:

Challenges

- Material Science & Development: Developing a reliable and high-quality 3D printing filament made primarily from bamboo is a significant challenge. This involves finding the right blend of bamboo fibers with polymers to ensure printability, strength, and durability while maintaining environmental sustainability.

- Consistency and Quality Control: Ensuring that the bamboo filament maintains consistent quality across batches is crucial. Natural materials like bamboo can have variations in their composition, which could affect the final print quality and mechanical properties.

- Printer Compatibility: The Bambu 3D Printer must be designed to handle the unique characteristics of bamboo-based filaments. This might require specialized extruders or temperature controls to optimize printing parameters and prevent issues like clogging or warping.

- Sustainability Certification: To appeal to environmentally conscious consumers, the entire production process, from sourcing bamboo to the disposal of by-products, needs to meet rigorous sustainability standards. Achieving certifications like Forest Stewardship Council (FSC) or Cradle-to-Cradle can be a complex and time-consuming process.

- Market Adoption: Convincing users, especially industrial clients, to switch from traditional plastic filaments to a relatively new and untested bamboo alternative requires demonstrating clear benefits, such as cost-effectiveness, environmental impact reduction, and comparable or superior performance.

- Economic Viability: The cost of producing bamboo filament and the printer itself must be competitive with existing alternatives. Balancing affordability with sustainability goals is crucial for market penetration.

The Road Ahead

- Research and Development: Continuous R&D efforts to improve the bamboo filament’s properties, reduce material costs, and enhance the printing process will be paramount.

- Partnerships: Collaborating with bamboo farmers, sustainable material researchers, and recycling experts can help streamline the supply chain and ensure responsible sourcing and processing.

- Innovation in Printer Design: Designing printers specifically tailored to bamboo filaments, with features that enhance efficiency, precision, and ease of use, will differentiate the Bambu 3D Printer in the market.

- Education and Marketing: Educating potential customers about the environmental benefits of using bamboo-based filaments and showcasing successful applications can drive demand and increase adoption rates.

- Scaling Production: As the technology matures and demand grows, scaling up production capabilities while maintaining quality control and sustainability standards will be essential.

- Exploring New Applications: Expanding into niche markets or applications where bamboo’s unique properties offer advantages, such as biodegradable prototypes, eco-friendly packaging solutions, or even construction components, could unlock new growth opportunities.

By addressing these challenges and leveraging the opportunities presented, the Bambu 3D Printer has the potential to revolutionize the 3D printing industry, offering a more sustainable alternative to conventional plastic-based printing materials. However, this journey will require a concerted effort in innovation, strategic partnerships, and effective communication to overcome the hurdles and pave the way for widespread adoption.

Conclusion: A New Era in Manufacturing

The Bambu 3D Printer symbolizes a paradigm shift in the world of manufacturing, marrying innovation, sustainability, and accessibility in a single package. Its ability to create intricate, functional designs using eco-friendly materials positions it as a pioneer in the quest for greener production methods. As technology advances and more industries embrace 3D printing, the Bambu stands at the forefront, empowering designers, educators, and manufacturers alike to push the boundaries of what is possible. In the years to come, its legacy will undoubtedly be marked by countless innovations and a profound impact on how we design, create, and manufacture our world.