Introduction

In the realm of personalized expression and branding, sticker printers have emerged as a versatile and exciting tool. From adding a touch of individuality to personal belongings to enhancing business marketing strategies, these nifty devices empower users to create custom stickers effortlessly. This comprehensive guide delves into the world of sticker printing, exploring its various aspects, benefits, and the considerations one should make when choosing the perfect sticker printer.

Understanding Sticker Printers: Technology and Types

In the realm of do-it-yourself creativity and professional branding, sticker printers have carved out a niche as indispensable tools. These compact marvels bring ideas to life by transforming digital designs into tangible, adhesive-backed creations. Delving deeper into the mechanics of sticker printing, we uncover two primary technological approaches: inkjet and thermal printing systems, each with its own set of strengths and applications.

Inkjet Technology: A Canvas for Colorful Creations

Inkjet sticker printers work by precisely ejecting minuscule droplets of ink onto a sticker sheet, meticulously layering these droplets to form vivid images and sharp text. Their color reproduction capabilities are exceptional, making them the go-to choice for users who prioritize rich hues and intricate details. Whether it’s reproducing a stunning landscape photograph or a detailed illustration, inkjet printers excel in versatility. However, they come with a trade-off: the need for regular ink cartridge replacements, which can be a recurring expense.

Thermal Printing: Speed and Durability Combined

On the other hand, thermal sticker printers employ heat to transfer images directly onto the sticker material. This technology is divided into two categories:

- Direct Thermal Printing: Utilizes chemically treated paper that darkens when heat is applied, creating the image. It’s swift and silent, perfect for quick, high-volume printing tasks like barcode stickers or basic labels. However, these prints can fade over time or when exposed to heat or sunlight.

- Thermal Transfer Printing: Involves a process where a heated ribbon melts ink onto the sticker substrate, resulting in durable, long-lasting prints resistant to water, scratches, and fading. This method is ideal for outdoor applications or whenever longevity is crucial, although it tends to be slightly more expensive due to the need for ribbon.

Within these broad technological classifications, sticker printers further diversify to cater to specific user needs:

- Desktop Models: Designed for home or small office use, these compact printers are easy to set up and use. They often balance affordability with functionality, suitable for occasional to moderate printing demands.

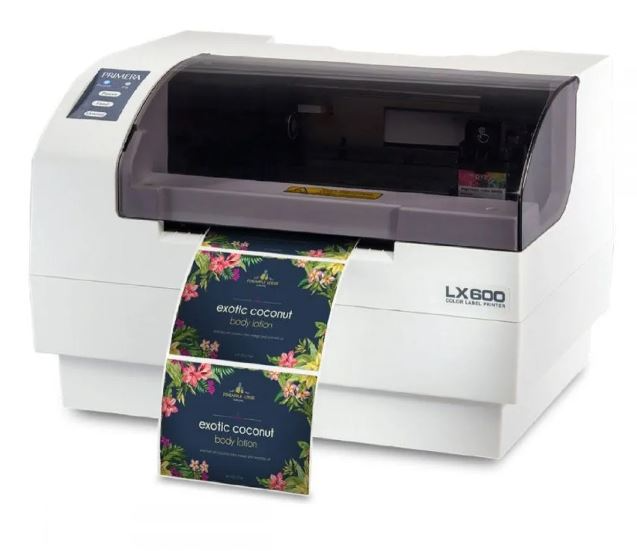

- Commercial Grade Printers: Built for heavy-duty performance, these machines are found in professional settings. They offer faster print speeds, higher resolution, and more durable components, capable of handling large volumes and continuous operation.

- Portable Printers: Ideal for on-the-go use, portable sticker printers are lightweight and battery-powered, enabling instant sticker creation at events, exhibitions, or remote job sites.

Making an Informed Choice

Deciding on the right sticker printer involves aligning your requirements with the features and benefits of each technology and type. For artists and hobbyists seeking color fidelity and detail, inkjet printers are a natural fit. Businesses with high-volume labeling needs or those requiring weather-resistant stickers will find thermal transfer printers more suitable. Always consider factors such as initial cost, running expenses, print quality, and the intended use environment to ensure your chosen printer meets both your creative aspirations and practical constraints.

Ultimately, understanding the underlying technology and the variety of sticker printer types available empowers you to make a well-informed decision, unlocking the full potential of personalized and professional sticker production.

Choosing the Right Sticker Printer: Key Considerations

Selecting the ideal sticker printer depends on several factors, including intended usage, budget, and desired output quality.

Usage Frequency

Casual users looking to print stickers occasionally might favor a compact, affordable inkjet model. Conversely, businesses requiring high-volume or daily printing would benefit from a more robust thermal printer, which offers faster print speeds and lower operating costs in the long run.

Print Quality

For those prioritizing vivid colors and fine details, inkjet printers are typically the better choice. However, if longevity and resilience against water and fading are important, thermal transfer printers provide more durable stickers.

Budget Constraints

Initial costs vary greatly between inkjet and thermal printers, with inkjets often being cheaper upfront. But don’t forget to factor in ongoing costs such as ink or ribbon replacements, which can tip the balance in favor of thermal printers for heavy users.

Creative Applications of Sticker Printing

Sticker printers unlock a world of possibilities, enabling users to express themselves artistically and promote businesses in innovative ways.

Personalization and Crafts

From scrapbooking to DIY projects, customized stickers add a personal touch to almost any item. With a sticker printer, users can design and print stickers featuring family photos, favorite quotes, or unique artwork, making it a favorite among hobbyists and craft enthusiasts.

Marketing and Branding

Small businesses and entrepreneurs leverage sticker printing to enhance brand visibility. Custom logo stickers can be affixed to packaging, promotional materials, or even as guerrilla marketing tactics on urban landscapes, creating mobile advertisements that stick around.

Events and Gifting

Stickers also serve as memorable giveaways at events or as part of gift packaging. Personalized stickers for weddings, birthdays, or corporate events can elevate the overall experience and leave a lasting impression on attendees.

Tips for Optimal Sticker Printing Experience

To get the best results from your sticker printer, follow these practical tips:

Design Preparation

Optimize your designs for sticker printing. Ensure images are high-resolution, and text is legible at the intended print size. Use vector graphics where possible for scalability without loss of quality.

Material Selection

Choose the right sticker paper or material based on your needs. Glossy finishes are great for colorful graphics, while matte is preferred for text-heavy stickers. Waterproof or vinyl materials are ideal for outdoor use.

Printer Maintenance

Regular cleaning and maintenance are crucial for consistent print quality. Follow the manufacturer’s guidelines to clean print heads, avoid paper jams, and prolong the life of your printer.

Conclusion

Sticker printers have transformed the way we personalize items and promote brands, offering a creative outlet with practical applications. By understanding the different types of printers, considering key factors before purchasing, and leveraging the myriad uses of stickers, individuals and businesses alike can harness the power of customization. With the right approach and care, a sticker printer becomes an invaluable asset, unlocking endless possibilities for self-expression and marketing alike.