Introduction

3D printing, an innovative technology that brings digital designs to life in three dimensions, has revolutionized the way we create, prototype, and manufacture objects. If you’re a beginner looking to explore this exciting realm, understanding the basics of 3D printers is essential. In this comprehensive guide, we’ll demystify the world of 3D printing, covering key concepts, types of 3D printers, materials, software, and practical tips to help you get started on 3D Printers for Beginners journey.

Understanding 3D Printing Basics

The 3D Printing Process

At its core, 3D printing involves translating a digital 3D model into a physical object through an additive manufacturing process. This process starts with creating or obtaining a 3D design using computer-aided design (CAD) software or by downloading pre-made models from online repositories. Once the design is ready, it’s sliced into numerous thin layers using specialized software called a slicer. The sliced file is then sent to the 3D printer, which deposits material layer by layer, following the sliced instructions, until the final object is formed.

Types of 3D Printing Technologies

There are several 3D printing technologies available, each with its own unique approach to material deposition and layer bonding. Some popular methods include:

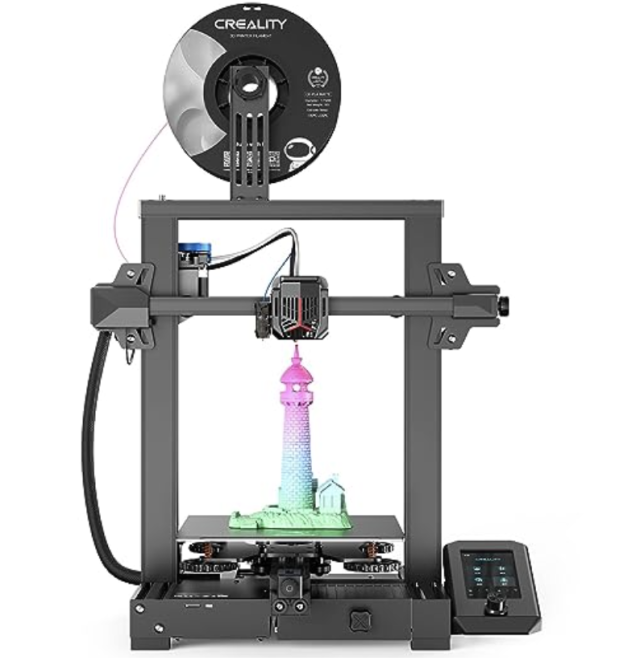

Fused Deposition Modeling (FDM): FDM printers use a heated nozzle to melt and extrude thermoplastic filament, which solidifies as it cools, forming each layer. FDM is the most widely accessible and affordable technology, ideal for beginners due to its simplicity and ease of use.

Stereolithography (SLA) and Digital Light Processing (DLP): These resin-based printers use UV light to cure liquid resin layer by layer, either by tracing the shape with a laser (SLA) or projecting an image of the layer onto a vat of resin (DLP). SLA and DLP produce highly detailed, smooth surfaces, making them suitable for intricate designs or prototyping.

Selective Laser Sintering (SLS): SLS printers use a laser to fuse small particles of powdered material, such as nylon or metal, into solid layers. SLS offers high strength, flexibility, and the ability to produce complex geometries without the need for support structures.

Understanding these technologies will help you choose the best 3D printer for your specific needs and budget.

Choosing Your First 3D Printer

Factors to Consider

When selecting your first 3D printer, consider the following factors:

Build Volume: Determine the maximum size of objects you want to print and choose a printer with an appropriate build area. Keep in mind that larger build volumes typically come with higher costs.

Ease of Use: Look for user-friendly features like automatic bed leveling, intuitive touchscreens, and straightforward setup processes. As a beginner, a printer that simplifies the learning curve will be invaluable.

Material Compatibility: Consider the type of materials you’d like to work with and ensure the printer supports them. For instance, if you’re interested in printing with various filaments or resins, opt for a versatile printer.

Budget: 3D printers range from budget-friendly desktop models to high-end industrial machines. Set a realistic budget and prioritize the features that matter most to you within that price range.

Community Support and Documentation: A strong community and comprehensive documentation can be invaluable resources for troubleshooting, learning new techniques, and accessing upgrades or modifications.

Exploring 3D Printing Materials

Thermoplastics (FDM)

Thermoplastics are the most common materials used in FDM 3D printing. Popular choices include:

PLA (Polylactic Acid): Easy to print, biodegradable, and available in a variety of colors and translucencies, PLA is an excellent choice for beginners.

ABS (Acrylonitrile Butadiene Styrene): More durable and heat-resistant than PLA, ABS requires a heated bed and can emit fumes during printing, making it better suited for experienced users with proper ventilation.

PETG (Polyethylene Terephthalate Glycol): Combining the ease of printing of PLA with the durability of ABS, PETG is a versatile, odorless, and food-safe option.

Nylon, TPU, and Other Specialty Filaments: These materials offer unique properties like flexibility, strength, or chemical resistance, expanding the possibilities for functional prints.

Resins (SLA, DLP)

Resins are liquid photopolymers cured by UV light. They offer high detail, smooth surfaces, and are commonly used for jewelry, dental models, and prototypes. Different resins have varying properties, such as hardness, flexibility, or transparency.

Powder-Based Materials (SLS)

SLS printers work with powdered materials like nylon, polyamide, or various metals. These materials provide excellent mechanical properties, making them suitable for functional parts, prototypes, or small-scale production.

Essential Software for 3D Printing

3D Modeling Software

To create custom 3D designs, you can use CAD software like Tinkercad (beginner-friendly), Fusion 360, or Blender (more advanced). Alternatively, download pre-made designs from websites like Thingiverse, MyMiniFactory, or Cults.

Slicing Software

Slicers convert 3D models into printable G-code files. Cura, Simplify3D, and PrusaSlicer are popular options, offering user-friendly interfaces and extensive customization options for print settings.

Tips for Successful 3D Printing

Preparing Your Prints

Model Optimization: Ensure your 3D model is manifold (watertight), has appropriate wall thicknesses, and is scaled correctly. Use mesh repair tools if necessary.

Orientation and Supports: Experiment with different print orientations to minimize warping, reduce support material usage, and improve print quality. Most slicers automatically generate supports; adjust settings as needed.

Bed Adhesion: Proper bed adhesion is crucial for successful prints. Use adhesive sprays, tapes, or build plates like PEI or glass to prevent parts from detaching during printing.

Maintaining and Troubleshooting Your Printer

Regular Maintenance: Clean the printer, check belts and bearings for wear, and lubricate moving parts according to manufacturer recommendations. Maintain a clean and dust-free printing environment.

Calibration: Periodically calibrate the printer’s bed leveling, extruder steps, and Z-offset to ensure accurate and consistent prints.

Troubleshooting Common Issues: Familiarize yourself with common problems like under-extrusion, over-extrusion, stringing, and layer shifting, and learn how to diagnose and fix them.

Expanding Your Skills and Creativity

Post-Processing Techniques

Enhance the appearance and functionality of your prints through post-processing techniques like sanding, painting, acetone vapor smoothing (for ABS), or chemical polishing (for resins).

Joining and Finishing Parts

Learn how to combine multiple printed parts using techniques like snap fits, dovetail joints, or adhesives. Explore methods like CNC machining, electroplating, or vacuum forming to add finishing touches or integrate other materials into your projects.

Engaging with the 3D Printing Community

Participate in online forums, attend workshops or meetups, and share your projects on social media platforms. Collaborate with others, learn from their experiences, and contribute to the ever-growing knowledge base of the 3D printing community.

Conclusion

In conclusion, 3D printing offers endless possibilities for creativity, innovation, and problem-solving. By understanding the basics, choosing the right printer and materials, mastering essential software, and continually expanding your skills, you’ll embark on a rewarding journey in the world of 3D printing. Start exploring today, and watch your ideas take shape layer by layer!